Overview

Project Number: S2940-1

Project Title: High Performance Insulation Materials & Processes (Phase I)

Period of Performance: OCT22 – SEP24

Objective

Advances in insulation material and installation technology provide an opportunity to reduce material cost, storage cost, installation labor, rework, craft scheduling flexibility, and improve the quality of ship insulation while staying within ship specifications. This project identified and evaluated new insulation technologies including new materials, tooling, and installation processes.

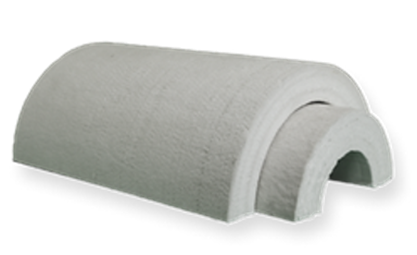

The purpose of this Composites Manufacturing Technology Center (CMTC) project was to focus on improvement opportunities for three of the primary applications of high-temperature insulation used on Navy ships high temperature equipment, N30 fire insulation, and removable valve covers. The first phase of the project provided an evaluation of existing materials, tools, and processes, along with identification of problem areas. Alternative products are identified and screened against requirements.

Information from this review was used to consolidate insulation products. New materials were recommended as options to reduce material cost and initial / rework labor costs. Insulation installation processes were compared, examined, and upgraded. New tools were studied and recommended to reduce installation labor and rework. Storage strategies were examined and upgraded, and more efficient insulation delivery to the job site should result. This effort should increase craft productivity, reduce rework, and improve scheduling flexibility. Candidate products identified in Phase 1 were piloted in Phase 2 for final selection and approval for implementation onboard ships.

Payoff

The anticipated labor savings of utilizing selected insulations for numerous applications, including fire insulation, high temperature insulation, and valve body insulation, were approximately $1.7M per DDG 51 Class destroyer with an anticipated $10.0M savings over five-years.

Implementation

Transition of the insulations, tools, and processes to implementation occurred soon after piloting and final approval in Phase 2. Implementation has accomplished initially where no conflict exists with the existing design. This involved replacing insulation materials, utilizing tools and implementing new processes in current ship construction practices. However, some of the materials, tools, and processes have to be phased into use with future ships.

*Prepared under ONR Contract N00014-21-D-7001 as part of the Navy ManTech Program.

*DISTRIBUTION STATEMENT A. Approved for public release: distribution unlimited. DCN# 024-11-6-309; Approval Date: 11/14/2024