Overview

Project Number: A2853

Project Title: Automated In-Process Inspection for Automated Composite Lamination

Period of Performance: MAY21 – APR24

Objective

The demanding performance requirements of modern composite structures are predicated on tightly controlling the tolerances of the as-built part. This duteous approach ensures that the as-designed part is manufactured within the established design limits. Defects that cause the part to deviate from the design can come from a wide variety of sources. One of the defining strengths of automated composite layup and forming is that it removes a considerable degree of the variability introduced by manual layup. Although automated layup and forming technologies provide a significantly more robust and repeatable process, automated manufacturing equipment is still susceptible to producing a part that violates specification tolerances. To detect, correct, and control these deviations, some form of inspection system is required.

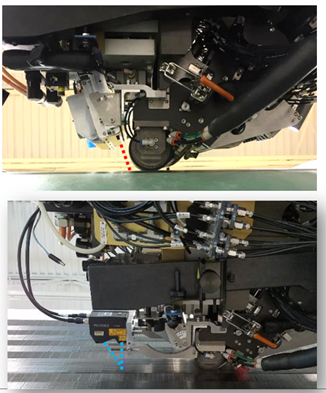

The current industry standard for inspection of composite parts is manual ply-by-ply inspection of the composite layup. This approach has a number of limitations and drawbacks that result in costly rework, excessive material consumption, and reduced production rates. An automated in-process inspection system has significant potential to mitigate and eliminate these aforementioned drawbacks of the current industry standard. This Composite Manufacturing Technology Center (CMTC) project, which includes Northrop Grumman and Fives, used a phased approach to develop and demonstrate an automated in-process inspection system capable of transitioning to production.

Payoff

The benefits of developing an automated solution for composite laminate inspection have a major payoff in process savings. Potential production rate increases, quality savings, and reduction in production material waste enable these possible process savings. Specific benefits were shown in inspection time on wing skin structures and human levels of detection accuracy for splices, twists, and missing tow defects. There are additional opportunities on current and future platforms, with larger benefits realized when the technology is applied at program start-up.

Implementation

The implementation of automated inspection technology on the F-35 Lightning II program will require input from the Joint Program Office (JPO), Lockheed Martin Aeronautics (LM-Aero), Northrop Grumman, and Fives. The initial intent was to pursue the transition of the technology onto automated fiber placement (AFP) machines used to produce nacelles on the F-35 Lightning II program. Due to program delays the system has only been demonstrated on wing skins on Fives Viper 6000 machines. The below updated strategy addresses the revised two-phase implementation strategy that is anticipated to start in FY2025:

1. Qualification and validation on FPM-5 for Wings.

2. Qualification and validation on nacelles.

*Prepared under ONR Contract N00014-21-D-7001 as part of the Navy ManTech Program.

*DISTRIBUTION STATEMENT A. Approved for public release: distribution unlimited. DCN# 2024-11-6-309; Approval Date: 11/14/2024