Overview

Project Number: T2990

Project Title: Low-Cost Ceramic Matrix Composite Material Evaluation

Period of Performance: FEB23 – FEB25

Objective

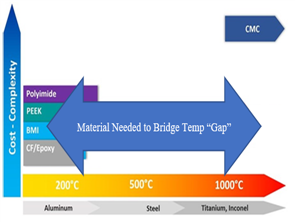

A growing number of Navy systems have been shown to benefit from structurally efficient, low-weight and high-temperature-resistant materials to achieve optimum performance. Examples include engine applications, hypersonic systems, and engine exhaust areas affected on both manned and unmanned rotary and fixed-wing aircraft, as well as potentially ships, for high-temperature applications that require flame, smoke, and toxicity requirements. These heat sensitive areas traditionally use high-temperature metallic alloys (titanium / Inconel, etc.) or Ceramic Matrix Composites (CMC) for temperature resistance. Metallic solutions have excellent temperature resistance but are expensive to manufacture and incur significant weight penalties. CMCs (such as carbon-carbon and carbon-silicon carbon) deliver exceptional performance at very high temperatures, but their complex processing and associated high costs have limited their widespread use. New material systems are becoming available which are classified as inorganic polymers that could potentially fill the needed material requirements. These inorganic polymers are derived from alumino-silicate-based geopolymer systems, and differ significantly from both organic polymers and conventional ceramic matrices. With this technology, these composites bring a lightweight and convenient alternative to metals and other materials for heat shields, ducts, etc.

To evaluate the performance of the system, the current state will be baselined. This Composites Manufacturing Technology Center (CMTC) project will identify, mature, and demonstrate a composite material and associated processing capable of high-temperature usage for Navy applications.

Payoff

Upon successful completion of the project, it is anticipated that a material system would be identified, characterized, and demonstrated that could withstand elevated temperatures and be processed into parts economically with straightforward manufacturing. With this technology, these composites bring a lightweight and convenient alternative to metals and other materials for heat shields, ducts, and other components. These materials are also used when superior fire, smoke, and toxicity properties are required.

Implementation

With successful project outcomes, it is anticipated that, a 6.3 Navy ManTech program will be established to facilitate technology transition to a Navy application.

*Prepared under ONR Contract N00014-21-D-7001 as part of the Navy ManTech Program.

*DISTRIBUTION STATEMENT A. Approved for public release: distribution unlimited. DCN# 2024-11-6-309; Approval Date: 11/14/2024